لوحة حائط من الصوف الصخري

مقاومة للحريق: الصوف الصخري مادة غير قابلة للاحتراق من الفئة أ، فعالة في منع انتشار الحرائق وتعزيز سلامة المباني.

العزل الحراري: بفضل موصليته الحرارية المنخفضة، يقلل الصوف الصخري من انتقال الحرارة، ويعزز عزل المباني، ويخفض استهلاك الطاقة.

عزل الصوت: يمتص بنيته المسامية الموجات الصوتية، ويقلل من انتقال الضوضاء، ويناسب الأماكن التي تتطلب عزلًا صوتيًا.

مقاومة التآكل: يتميز الصوف الصخري بخصائص كيميائية مستقرة، ويقاوم التآكل الحمضي والقلوي، ويتكيف مع مختلف البيئات، ويتمتع بعمر خدمة طويل.

قوة ضغط عالية: يتميز ببنية محكمة ومقاومة ضغط جيدة، مما يجعله مناسبًا للاستخدامات التي تتطلب أحمالًا ثقيلة.

Product Introduction

With green building trends rising, Rockwool Wall Panels are key innovations. Featuring metal-polyurethane load-bearing structures for insulation and structural integrity, they offer high-performance fire resistance and soundproofing. Modular design simplifies installation/maintenance, while waterproof/fireproof features enhance durability. A versatile sustainable solution for modern green architecture.

Color Selection

Uncover a dynamic range of steel sheet color options! From the refined subtlety of ivory and beige to the spirited allure of emerald green and lime, and the bold magnetism of raspberry and hot pink, our extensive color palette caters to every aesthetic inclination. Boasting a broad collection of both timeless and distinctive shades, we streamline the process of selecting the perfect color to flawlessly align with your design visions and project needs.

Certifications

Our company holds CE, ISO 9001, SGS, and FM certifications, ensuring compliance with EU standards, rigorous quality management, strict testing, and fire safety norms. These credentials reflect our commitment to excellence, reliability, and industry leadership.

Rockwool wall panels are advanced insulation and fire-resistant building materials widely used in residential, commercial, and industrial construction. Known for their thermal insulation, acoustic performance, and fire resistance, these panels combine rockwool (mineral wool) cores with various facings to deliver a high-performance wall cladding solution.

This article provides a detailed technical overview of rockwool wall panels, covering material composition, engineering principles, industry standards, regulatory requirements, installation best practices, and maintenance guidelines to help architects, engineers, and contractors make informed decisions.

What Are Rockwool Wall Panels?

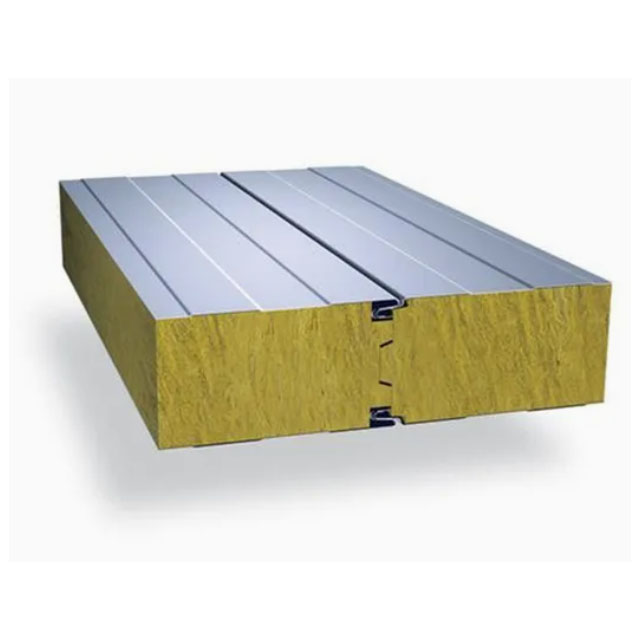

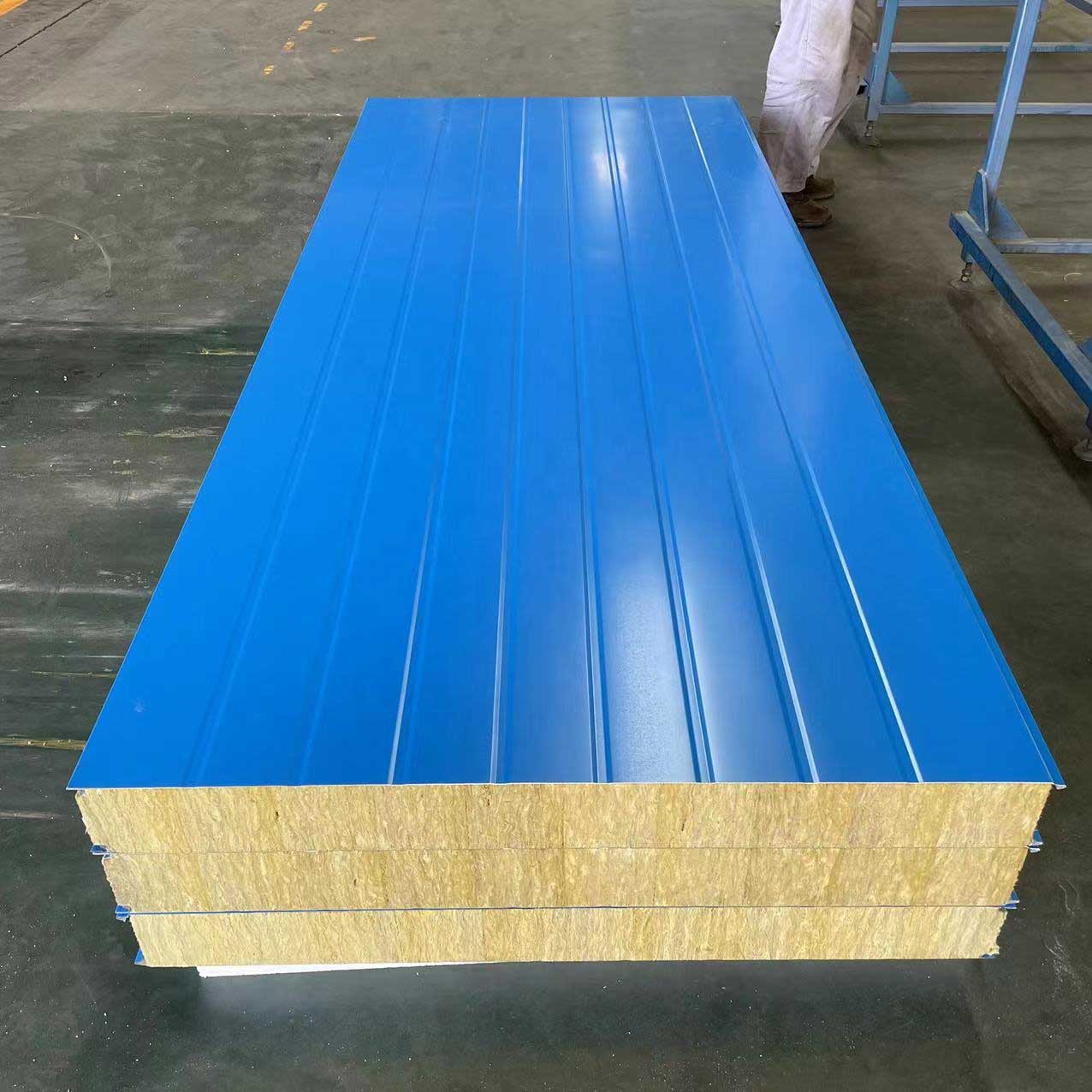

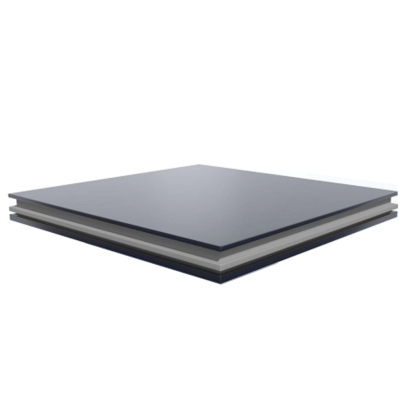

Rockwool wall panels consist of a core made from rockwool insulation fibers, sandwiched between facing layers such as galvanized steel, aluminum, or coated steel sheets. These panels are designed to provide thermal insulation, fire protection, and sound attenuation while also serving as a durable exterior or interior cladding.

Material Composition and Engineering Principles

Core Material: Rockwool (Mineral Wool)

Composition: Made from natural basalt rock and recycled slag spun into fibrous wool.

Properties: High melting point (~1,000°C), non-combustible, low thermal conductivity (typically 0.034–0.040 W/m·K).

Density: Typically ranges from 80 to 180 kg/m³ depending on application.

Fire Performance: Classed as A1 non-combustible under EN 13501-1.

Facing Materials

Galvanized Steel: Common for exterior panels; thickness ranges from 0.4 mm to 0.7 mm.

Aluminum or Aluminum Composite: Lightweight and corrosion resistant.

Coatings: Polyester, PVDF, or PE coatings for enhanced weather resistance and aesthetic options.

Panel Construction

Core thickness varies from 30 mm to 150 mm depending on insulation requirements.

Panels typically feature tongue-and-groove or shiplap edges for secure jointing.

Panels can be manufactured in sizes up to 1200 mm width and lengths up to 12 meters.

Key Technical Characteristics

| Parameter | Typical Value/Range |

|---|---|

| Thermal Conductivity | 0.034 – 0.040 W/m·K |

| Fire Rating | Euroclass A1 (non-combustible) |

| Sound Insulation | Rw up to 50 dB depending on thickness |

| Density | 80 – 180 kg/m³ |

| Panel Thickness | 30 mm to 150 mm |

| Facing Thickness | 0.4 mm – 0.7 mm steel/aluminum |

| Water Absorption | ≤ 1% (EN 1609) |